ALIVEFORM by Comme Conception

Footwear innovation with 3D printing

ALIVEFORM is a Tokyo-based experimental footwear brand specialising in 3D-printed shoes. The brand was established in 2022 by Pek Shun Ping, a Singaporean designer, who works under the digital moniker of Comme Conception. ALIVEFORM draws inspiration from various objects and elements of nature, such as perforated leaves and growth patterns of corals, which Pek then brings to life with 3D printing.

Pek started the brand to explore the possibilities of 3D printing technology. “The design techniques for regular footwear are well established, and in a saturated footwear market, I do not see myself creating just another footwear brand,” says Pek. “Instead, with 3D printing, I see the value in the unexplored and untapped potential of what printed shoes could be.”

ALIVEFORM provides a more ecological solution to footwear manufacturing. Pek elaborates, “The ability to print on demand, creating pairs only when needed eliminates the waste of leftover stocks.” He adds, “The brand’s independent production process and the use of a singular material also unclutter the complex supply chains within the industry.”

Monstera Stomper, 2022. Image courtesy of ALIVEFORM.

Pek was introduced to 3D printing when he pursued a BFA in Industrial and Product Design at Nanyang Technological University. After graduating in 2015, he worked as an industrial designer at a multidisciplinary agency, where he created 3D modelling and visualisations for product concepts as a part of his day-to-day job. Seeing the potential of the technology, Pek became keen on printing actual products rather than just prototypes.

In 2017, Adidas introduced Futurecraft 4D, the world’s first 3D-printed soles. “This further sparked my interest in exploring the opportunities the technology can offer and heavily influenced my decision to pursue a career as a footwear designer,” Pek shares. Around the same period, he began to document his design visualisations, 3D prototypes, and material explorations through @commeconception, an Instagram account that serves as a digital archive of his works.

And in 2019, Pek participated in the ‘Fueling the Future of Footwear’ master class and design competition held by Pensole Footwear Design Academy in partnership with Foot Locker and Asics. He won first prize. He then worked for Tokyo-based brand Foot Industry from 2021, before eventually establishing ALIVEFORM the following year.

Pek is constantly experimenting with new design possibilities. “ALIVEFORM’s footwear designs are created through the understanding of the different techniques and types of materials,” he explains. In his practice, he works with two 3D printing techniques: fused deposition modelling (FDM), which builds parts by melting thermoplastic polyurethane material into many stacked layers, and resin printing technique that forms objects from liquid resin that solidifies when exposed to UV light.

For the most part, ALIVEFORM uses the latter as the main technique to create footwear. “I usually try to classify which of these 3D printing methods works best for the design and think about how to bring the uniqueness of this material and/or technology,” he remarks, “though there were some occasions where the ideas or concepts came first, which required the team to carry out a reverse engineering approach.”

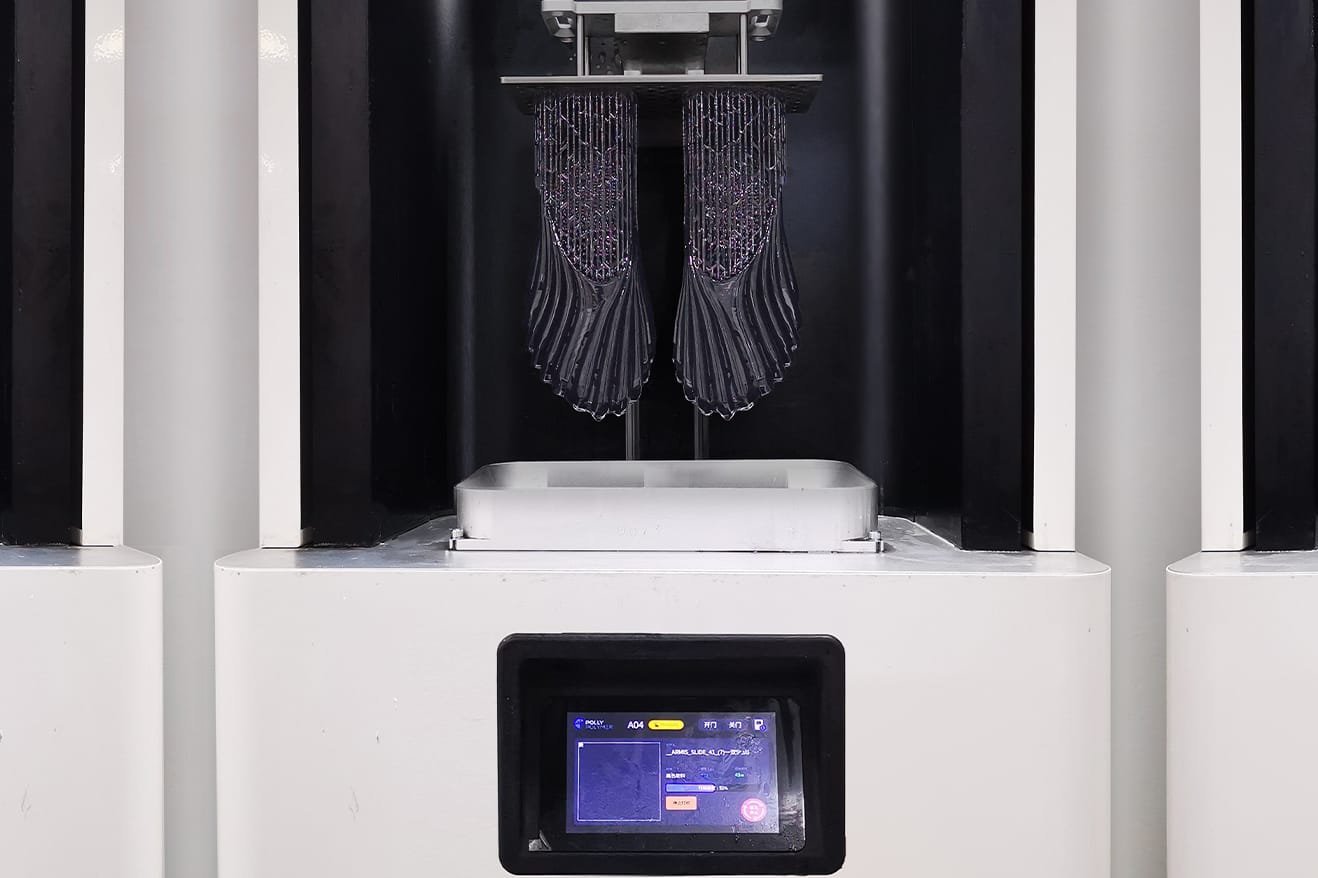

3D printing process of ARMIS collection. Image courtesy of ALIVEFORM.

The next step in the production is analysing the printability of the design and creating the 3D modelling in the form of a digital file, which is then sent for sample printing. ALIVEFORM’s products are made from resin material printed with a stereolithography (SLA) 3D printer that uses UV light to cure the liquid resin into layers.

The printing process of each shoe parallels growth in nature. “The build plate is attached to the printer and lowered into a photosensitive resin tank. The ultraviolet light from under the tank then flashes and cures the area matching the shoe’s cross-section on the resin layer,” describes Pek. “As each layer is printed, the build platform moves up a layer. The building up of successive layers of materials creates the completed shoe.”

The prototypes are then tested to make sure they fulfil the functional needs of each part of the shoes and are comfortable for wearers. The inner structure of ALIVEFORM’s shoes is constructed of cross-sectional lattices with different densities, depending on which area of foot it covers. For example, the foot cushioning at the top has a softer density for comfort, whereas the soles are more rigid for durability. According to Pek, paying attention to both design and wearability is the main challenge of the process. “As much as the possibilities in the designs, there needs to be a consideration of who would be wearing them and how,” he says. “I think learning to find that balance is a significant process of growing the brand and understanding my audience.”

While a common misconception about 3D-printed shoes is that they are not ergonomic, 3D printing has demonstrated the flexibility to customise the shoes to accommodate different foot sizes, shapes, and conditions, which could cater to an extensive range of target audiences. It can allow for the reconstruction of the inner structure for better performance, for example.

Coral Runners, 2020. Image courtesy of Comme Conception.

Biomimetic Footwear V1.0, 2022. Image courtesy of Comme Conception.

3D-printed shoes prototypes, 2020-2022. Image courtesy of Comme Conception.

Pek often finds design inspiration when observing nature. “Each of these observations comes from the essence of what is to be conveyed and amplified through design,” he explains. One notable nature-inspired prototype from his earlier works is the Coral Runner, a seamless shoe design made in 2020 featuring tube patterns on the surface inspired by brain corals. Another example is Biomimetic Footwear V1.0, a design conceptualised in 2022 for an online webinar class Pek tutored, in collaboration with Design Morphine, a global creative hub and education institution. The footwear series parallels the anatomy of transparent fish species.

Monstera Stomper, 2022. Image courtesy of ALIVEFORM.

TOPO-01, a collaboration with House of Errors, 2023. Image courtesy of ALIVEFORM

As for more recent designs, Pek launched the Monstera Stomper in 2022, which was ALIVEFORM’s product debut. The shoes adopted an oversized silhouette with perforated textures inspired by the leaves of the monstera plant.

Campaign image of ARMIS collection, featuring garments and accessories from Ryaw, 2023. Image courtesy of ALIVEFORM.

Campaign image of ARMIS collection, featuring garments and accessories from Ryaw, 2023. Image courtesy of ALIVEFORM.

Last March, the ARMIS collection replicated the resilient textures and shapes of cacti and seashells that function as natural protective shields. ARMIS comes with four style variations and was developed from a prototype Pek made in 2020 for a design competition held by the footwear community, Laceless Design. The collection was accompanied by campaign images featuring garments and accessories from Ryaw, a Japanese menswear label. Most recently, ALIVEFORM also worked on a collaboration with London-based streetwear brand, House of Errors. Together, they introduced TOPO-01, a limited-edition laceless footwear featuring a layered topography-derived texture.

Product packaging made out of mycelium. Image courtesy of ALIVEFORM.

The process of creating mycelium packaging. Image courtesy of ALIVEFORM.

Apart from nature-inspired designs, ALIVEFORM also works with bio-based materials for their brand collateral as a further commitment to their eco-friendly values. This includes the shoe's packaging box made of mycelium or mushroom roots, which can be used as plant fertiliser, and using FSC-certified paper sleeves made from corn as a biodegradable alternative.

In an effort to introduce its 3D-printed footwear to a wider scope of audience, ALIVEFORM has held physical showcases. Its designs are currently displayed at ‘Sneakertopia: Step Into Street Culture’, an exhibition that opened at ArtScience Museum in Singapore on 25 February and runs through 30 July. The display line-up includes the Monstera Stomper, ARMIS collection, and TOPO-01. Additionally, the exhibition features resin material samples printed in the form of lattices used for the shoe’s inner construction, as well as wall texts and videos explaining the 3D printing process.

Another recent offline event was a pop-up store in Tokyo accompanying the launch of TOPO-01 shoes in collaboration with House of Errors earlier this May. Pek plans to further expand the brand’s physical presence. “The experience of viewing the shoes in person is different from just seeing them on screen,” he remarks.

ARMIS LOW +, 2023. Image courtesy of ALIVEFORM.

Pek hopes that ALIVEFORM could lay the groundwork for a new era of footwear, using his growing influence to shine a light on the innovations 3D printing offers. However, it will take more than one brand to push the movement forward. He shares, “ALIVEFORM and other 3D-printed footwear brands such as Scry and Zellerfeld, are helping to normalise and pave the way for mass adoption.”

As the industry starts to embrace 3D printing technology as a multifaceted tool, Pek wishes to see more brands exploring the technology in the future. “ I think most major brands will be a part of it in due course.” he closes. And with that, ALIVEFORM is set to acquaint its 3D-printed shoes to expand its reach.

Learn more about ALIVEFORM’s products here or on Instagram at @aliveform.bio.

Visit ’Sneakertopia: Step Into Street Culture’ from 25 February to 30 July 2023 at the ArtScience Museum.